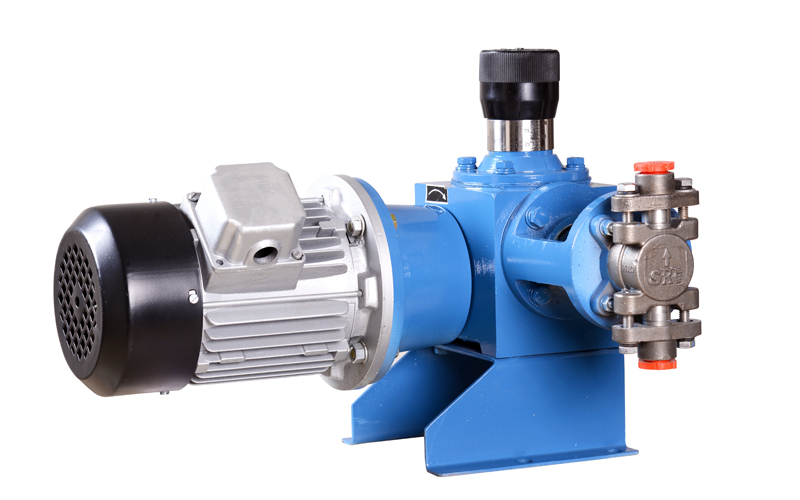

Description of Functioning: In this type of pump the Plunger is directly in contact of Liquid. It is Sealed by Special Packings to ensure minimum leakages.

Suction Stroke: When The Plunger moves backwards the it creates Vacuum & Discharge valve is closed & Suction valve opens allowing liquid to enter into the chamber.

Discharge Stroke: When the plunger moves forwards the it creates pressure & suction Valve is close & discharge Valve opens discharging fluid in the outlet pipe.

Applications:

- Dosing against High pressure

- Where High Accuracy is required

- Simple to Operate & Maintain

- Suitable for use for Handling Chemicals Compatible with SS 316 OR any other Metals Only.

Key Design Features

- High flow rates of 0.5 liters/hr to 12000 liters/hr & high pressures of 400 Kg/sq. cm. can be achieved.

- Steady State metering accuracy of + /- 1 % of pump output, at single setting of stroke from 10% - 100% (Turn down ratio 10:1).

- Reproducibility (Repeatability) better than +/- 2.5 % of set point.

- Easily handles viscous fluids. They are compatible with most of fluids.

- Positive return of plunger and variable stroke mechanism allows linear relationship between control stroke settings and stroke length.

- They have Low NPSHR requirement.

- Simplex and Multiplex arrangements of pumps available for universal use.

- Heating or cooling jackets for liquid head is also available.

Standard Models

| Sr. No. | Pump Model | Capacity Max(L.P.H.) | Pressure Max (Kg./Sq.Cm) |

|---|---|---|---|

| 1. | SL 10 | 196 | 115 |

| 2. | SL 20 | 1085 | 40 |

| 3. | SL 35 | 3590 | 310 |

| 4. | SL 60 | 6155 | 405 |