KOMTER

- Variable Speed

- Direct Driven

- Interior Permanent Magnet Motor

Compressed air drives your processes and with it the operational efficiency and performance of your company. With this principle in mind. KOMTER has designed a range of variable speed, oil-injection screw compressors with iPM motor technology to offer your business a compressed air solution that adds value and saves you money at the same time.

Why energy efficiency?

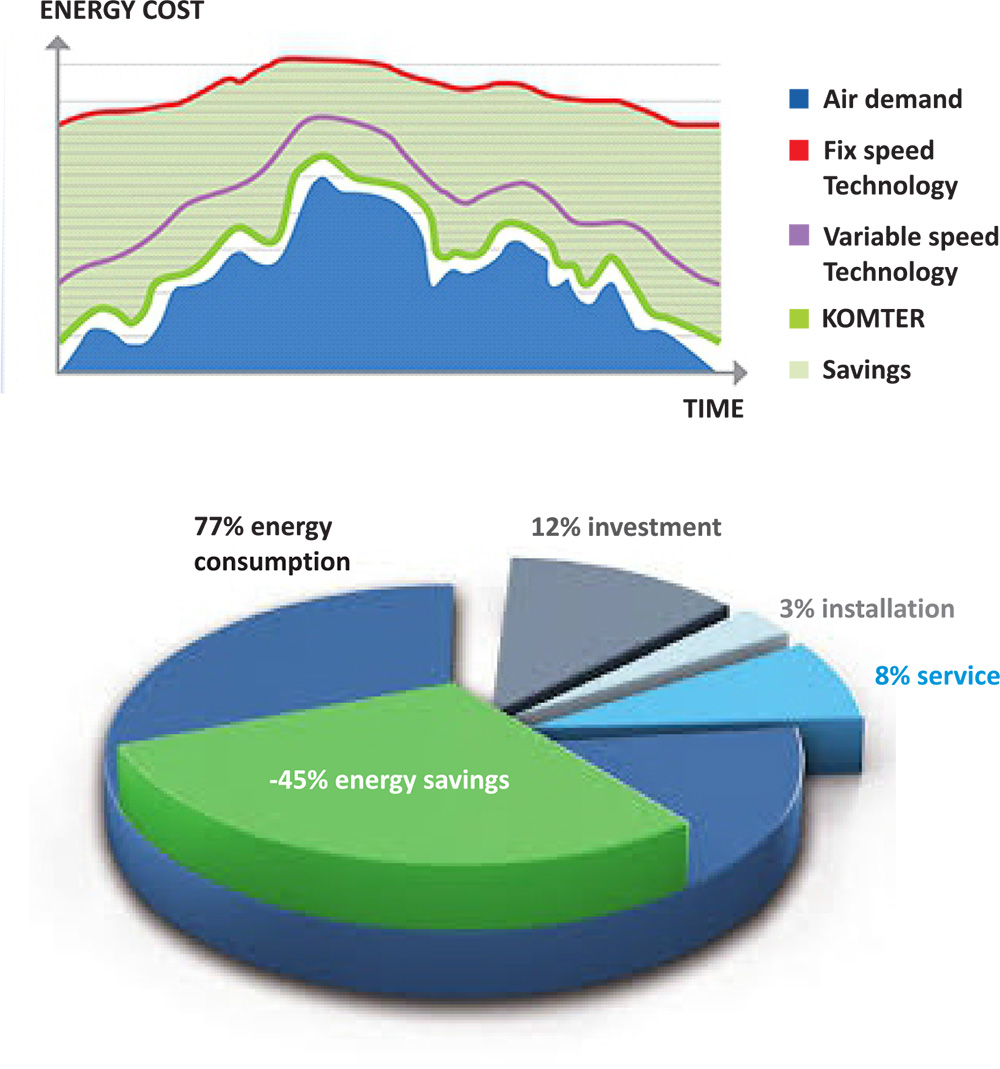

Energy costs represent about 70% of the total operating cost of your compressor over a 5-year period. That is why efficiently reducing the energy consumption of your compressed air installation should be a major focus.

Why Variable Speed?

As a majority of customers have a variable demand for compressed air, a variable speed compressor is superior vs a fixed speed compressor in terms of energy savings by perfectly matching air supply to air demand and avoiding unload losses.

Why KOMTER?

The KOMTER range combines variable speed technology with our new and highly efficient drive train with iPM motor technology and evolved the energy efficiency of variable speed compressors to a new level, resulting in energy savings of up to 45%.

Minimal Energy Costs

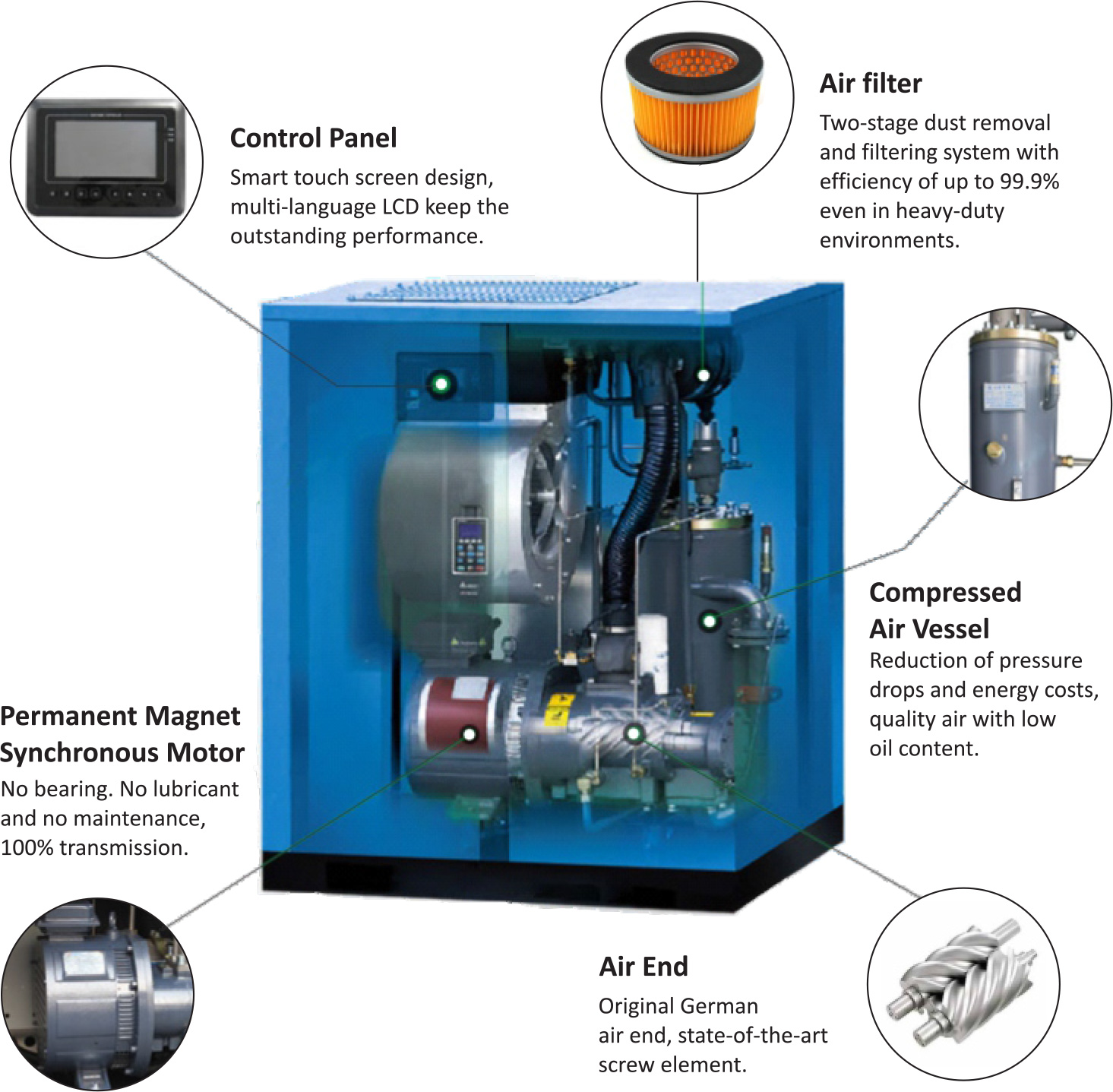

- More compressed air for less energy thanks to newest generation of screw elements

- Significant energy savings through 1E4 Super Premium Efficiency motor

- Minimal losses thanks to integrated direct drive transmission

- Instant savings bought by imperium variable speed technology vs. traditional fixed speed compressors.

Userfriendly Operation & Maintenance

- Large 4.3" graphical controller with touchscreen

- Integrated connectivity helps you optimize and save energy

- All consumables are at easy reach for fast service and minimal downtime of your compressor

- The coolers are mounted on gliding rails and can easily be dragged out and cleaned, making service a one-person job

- Low noise radial fan as standard

Reliable productivity & operational efficiency

- German designed interior permanent magnet (iPM) motor with innovative oil-cooling technology for optimal cooling at all speeds and conditions

- In-house designed Imperium inverter, tailor-made for screw compressor applications.

- Maintenance-free components enable higher uptime and increased productivity

Simple installation

- Compact and all in one system Innovative design

- Easy and full protected transport Placement with forklift (2 lifting points) or transpallet (1 lifting point)

- No special foundation needed

A peace of mind investment

- Quality filtration with long lifetime protects internal components and increases lifetime

- Packaged in a proven canopy design with already thousands of installations around the globe.

| Model | Work Pressure | Capacity | Power | Noise | Connection BSP |

Dimension | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bar | psi | CFM | HP | Kw | DB(A) | LxWxH(mm) | Kg | ||||

| KPM-10 | 8-10 | 145 | 9-42 | 10 | 7.5 | 56 | 3/4" | 780x600x1020 | 260 | ||

| KPM-15 | 8-10 | 145 | 14-69 | 15 | 11 | 56 | 1" | 1050x700x1150 | 330 | ||

| KPM-20 | 8-10 | 116 | 18-92 | 20 | 15 | 56 | 1" | 1050x700x1150 | 350 | ||

| KPM-30 | 8-10 | 116 | 29-138 | 30 | 22 | 60 | 1" | 1300x880x1160 | 465 | ||

| KPM-40 | 8-10 | 145 | 40-204 | 40 | 30 | 60 | 1" | 1300x880x1160 | 550 | ||

| KPM-50 | 8-10 | 145 | 50-240 | 50 | 37 | 68 | 1.5" | 1460x1025x1380 | 630 | ||

| KPM-60 | 8-10 | 145 | 60-288 | 60 | 45 | 68 | 1.5" | 1460x1025x1380 | 850 | ||

| KPM-75 | 8-10 | 145 | 70-353 | 75 | 55 | 68 | 2" | 1900x1250x1600 | 1200 | ||

| KPM-100 | 8-10 | 145 | 100-501 | 100 | 75 | 70 | 2" | 1900x1250x1600 | 1300 | ||

* Note: On continuous engineering improvements, technical specifications are subject to change without notice.

| Model | Work Pressure | Capacity | Power | Noise | Connection BSP |

Dimension | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bar | psi | CFM | HP | Kw | DB(A) | LxWxH(mm) | Kg | ||||

| KPM 15-16 | 14-16 | 232 | 7-32 | 15 | 11 | 66 | 3/4" | 1050x750x1000 | 260 | ||

| KPM 20-16 | 14-16 | 232 | 10-46 | 20 | 15 | 66 | 3/4" | 1050x750x1000 | 300 | ||

| KPM 30-16 | 14-16 | 232 | 20-78 | 30 | 22 | 68 | 1" | 1380x850x1100 | 340 | ||

| KPM 50-16 | 14-16 | 232 | 30-124 | 50 | 37 | 70 | 1.5" | 1470x1000x1380 | 450 | ||

* Note: On continuous engineering improvements, technical specifications are subject to change without notice.